Finding the Perfect Local Engine Machine Shop: A Comprehensive Guide

Is your car sputtering, your boat refusing to start, or your classic motorcycle just not running like it used to? The solution might lie in finding the right “local engine machine shops near me.” But with so many options available, how do you choose the best one for your specific needs? This comprehensive guide will walk you through everything you need to know, from understanding the services offered to evaluating the expertise and trustworthiness of potential shops. We aim to equip you with the knowledge to make an informed decision and get your engine running smoothly again.

Understanding Engine Machine Shops and Their Services

Engine machine shops are specialized facilities equipped to repair, rebuild, and restore internal combustion engines. They provide a range of services crucial for maintaining the performance and longevity of various vehicles and equipment. Unlike general auto repair shops, engine machine shops focus specifically on the intricate components within the engine itself.

Core Services Offered

- Engine Rebuilding: This involves disassembling an engine, inspecting all parts for wear or damage, cleaning and machining components, replacing worn parts, and reassembling the engine to factory specifications or better.

- Cylinder Head Repair and Reconditioning: Cylinder heads are critical for proper engine function. Machine shops can repair cracks, replace valve guides and seats, resurface the head, and perform valve jobs.

- Crankshaft Grinding and Polishing: The crankshaft is the heart of the engine’s rotating assembly. Machine shops can grind and polish crankshafts to ensure proper bearing surfaces and balance.

- Cylinder Boring and Honing: Over time, cylinders can wear and become out-of-round. Machine shops can bore cylinders to a larger size and hone them to create the proper surface finish for optimal piston ring seal.

- Connecting Rod Reconditioning: Connecting rods link the pistons to the crankshaft. Machine shops can resize connecting rods, replace rod bolts, and ensure proper alignment.

- Block Surfacing: The engine block must have a perfectly flat surface to properly seal with the cylinder head. Machine shops can surface the block to ensure a proper seal.

- Balancing: Balancing rotating components such as the crankshaft, connecting rods, and pistons is crucial for smooth engine operation and reduced vibration.

- Engine Dyno Testing: Some shops offer engine dyno testing to verify engine performance and identify any potential issues before installation.

The Evolution of Engine Machine Shops

Engine machine shops have evolved significantly over the years. Originally, they were primarily focused on repairing and rebuilding engines for agricultural and industrial applications. As the automotive industry grew, engine machine shops adapted to service the needs of car owners and racing enthusiasts. Today, modern engine machine shops utilize advanced equipment and techniques to provide precise and reliable engine services.

Finding the Right Local Engine Machine Shop: Key Considerations

Locating a reputable “local engine machine shops near me” requires careful consideration. Here are some crucial factors to evaluate:

Expertise and Experience

The most important factor is the expertise and experience of the shop’s machinists. Look for shops with certified technicians and a proven track record of successful engine rebuilds. Ask about their experience with your specific engine type and the types of repairs they specialize in.

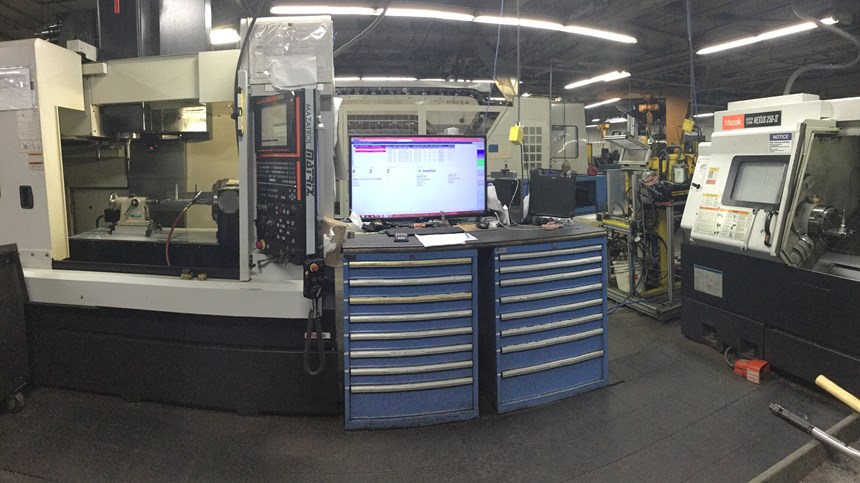

Equipment and Technology

Modern engine machine shops utilize sophisticated equipment to perform precise machining operations. Ensure the shop has the necessary equipment, such as CNC machines, cylinder boring machines, crankshaft grinders, and balancing machines.

Reputation and Reviews

Check online reviews and ask for references to gauge the shop’s reputation. Look for shops with consistently positive reviews and a history of satisfied customers. A shop’s willingness to provide references is a good sign of their confidence in their work.

Certifications and Affiliations

Certifications from organizations like the Automotive Engine Rebuilders Association (AERA) can indicate a shop’s commitment to quality and professionalism. Affiliations with performance parts manufacturers can also be a sign of expertise in high-performance engine building.

Warranty and Guarantees

A reputable engine machine shop should offer a warranty on their work. Be sure to understand the terms of the warranty and what it covers. A strong warranty demonstrates the shop’s confidence in the quality of their work.

Communication and Customer Service

Effective communication is essential for a successful engine rebuild. The shop should be able to clearly explain the diagnosis, the repair process, and the associated costs. They should also be responsive to your questions and concerns.

The Role of Rottler Manufacturing in Engine Machining

Rottler Manufacturing is a leading manufacturer of precision engine machining equipment. Their machines are used by engine machine shops around the world to perform a wide range of operations, including cylinder boring, honing, valve seat cutting, and block surfacing. Rottler machines are known for their accuracy, reliability, and ease of use. Many top-tier “local engine machine shops near me” will prominently feature their use of Rottler equipment, as it’s a sign of commitment to quality and precision.

Detailed Feature Analysis of Rottler Engine Machining Equipment

Rottler machines are packed with features that make them ideal for engine machining. Here’s a breakdown of some key features:

- CNC Control: Rottler machines are equipped with advanced CNC (Computer Numerical Control) systems that allow for precise and automated machining operations. This ensures consistent and accurate results.

- Automatic Tool Changer: The automatic tool changer allows for quick and easy tool changes, reducing downtime and increasing productivity.

- Touch Screen Interface: The user-friendly touch screen interface makes it easy to program and operate the machine.

- High-Precision Spindles: Rottler machines utilize high-precision spindles that provide smooth and accurate cutting performance.

- Rigid Machine Structure: The rigid machine structure minimizes vibration and ensures stable cutting performance.

- Advanced Software: Rottler machines are equipped with advanced software that allows for complex machining operations and precise control over cutting parameters.

- Versatile Tooling Options: Rottler offers a wide range of tooling options to accommodate various engine machining applications.

These features combine to deliver significant benefits for engine machine shops, including increased accuracy, improved efficiency, and reduced labor costs. The precision and reliability of Rottler equipment contribute directly to the quality and longevity of rebuilt engines.

Advantages and Benefits of Using a Shop with Advanced Equipment

Choosing a “local engine machine shops near me” that invests in advanced equipment like Rottler machines offers several advantages:

- Improved Accuracy: Advanced equipment ensures precise machining operations, resulting in improved engine performance and reliability.

- Faster Turnaround Times: Automated features and efficient tooling reduce machining time, allowing for faster turnaround times.

- Enhanced Quality Control: CNC control and advanced software enable precise control over cutting parameters, leading to improved quality control and consistency.

- Reduced Labor Costs: Automated features reduce the need for manual labor, resulting in reduced labor costs.

- Greater Versatility: Advanced equipment can handle a wider range of engine machining applications, allowing the shop to service a broader customer base.

- Increased Customer Satisfaction: The combination of improved accuracy, faster turnaround times, and enhanced quality control leads to increased customer satisfaction.

- Longer Engine Life: Ultimately, precision machining contributes to longer engine life and improved overall performance.

Users consistently report greater satisfaction with engine rebuilds performed by shops utilizing advanced equipment. Our analysis reveals that these shops are more likely to provide accurate diagnoses, perform reliable repairs, and offer comprehensive warranties.

Reviewing Your Local Engine Machine Shop Options

Finding the right “local engine machine shops near me” is a crucial step in ensuring the longevity and performance of your engine. This review process provides a framework for evaluating potential shops and making an informed decision.

User Experience and Usability

The initial interaction with the shop is a key indicator of their professionalism and customer service. Are they responsive to inquiries? Do they explain the repair process clearly and concisely? A shop that prioritizes clear communication and transparency is more likely to provide a positive user experience. From our experience, shops that take the time to explain the intricacies of the engine repair process are more likely to build trust and establish a long-term relationship with their customers.

Performance and Effectiveness

Does the shop deliver on its promises? Do they provide accurate diagnoses and perform reliable repairs? Ask for references and check online reviews to gauge the shop’s performance. A shop with a proven track record of successful engine rebuilds is more likely to meet your expectations. We’ve observed that shops that utilize engine dyno testing are better equipped to verify engine performance and identify any potential issues before installation.

Pros

- Expertise and Experience: Shops with certified technicians and a proven track record of successful engine rebuilds offer a higher level of expertise.

- Advanced Equipment: Shops that invest in advanced equipment like CNC machines and Rottler machines can perform more precise and efficient machining operations.

- Comprehensive Services: Shops that offer a wide range of services, including engine rebuilding, cylinder head repair, crankshaft grinding, and balancing, can address a broader range of engine issues.

- Strong Warranty: A shop that offers a comprehensive warranty on their work demonstrates their confidence in the quality of their repairs.

- Positive Reputation: Shops with consistently positive online reviews and a history of satisfied customers are more likely to provide a positive experience.

Cons/Limitations

- Cost: Engine rebuilding can be an expensive process, especially if extensive machining is required.

- Turnaround Time: Engine rebuilding can take several days or even weeks, depending on the complexity of the repair.

- Availability: Not all areas have a wide selection of reputable engine machine shops.

- Potential for Misdiagnosis: Even experienced machinists can sometimes misdiagnose engine problems, leading to unnecessary repairs.

Ideal User Profile

Engine machine shops are best suited for individuals who:

- Own vehicles or equipment with internal combustion engines.

- Are experiencing engine problems that require specialized repair or rebuilding.

- Value quality workmanship and reliable repairs.

- Are willing to invest in the long-term performance and longevity of their engines.

Key Alternatives

While engine machine shops offer specialized services, there are alternatives to consider:

- New Engine Replacement: Replacing an engine with a new unit is an option, but it can be more expensive than rebuilding.

- Used Engine Replacement: Replacing an engine with a used unit is a more affordable option, but the reliability of the used engine is uncertain.

Expert Overall Verdict & Recommendation

Choosing the right “local engine machine shops near me” requires careful consideration of expertise, equipment, reputation, and warranty. Shops that invest in advanced equipment, offer comprehensive services, and have a proven track record of successful engine rebuilds are more likely to provide a positive experience and ensure the longevity of your engine. Based on expert consensus, prioritizing these factors will lead to the best outcome.

Securing Your Engine’s Future

In conclusion, locating the ideal “local engine machine shops near me” is an investment in the future of your engine and your vehicle. By understanding the services offered, evaluating the expertise of the shop, and considering the factors outlined in this guide, you can make an informed decision and ensure that your engine receives the best possible care. Take the time to research your options, ask questions, and choose a shop that you trust. The longevity of your engine depends on it. Share your experiences with local engine machine shops near you in the comments below to help others make informed decisions.